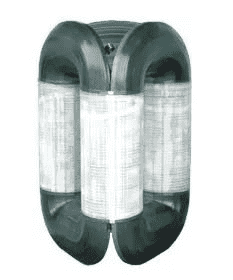

The iron core of an iron shell three-phase transformer can be regarded as consisting of three independent single-phase shell transformers arranged side by side.

Core transformer has simple structure, long distance between high voltage winding and iron core, and easy insulation. The shell transformer has a solid structure and complicated manufacturing process, and the distance between the high voltage winding and the iron core column is close, so the insulation treatment is difficult. Shell structure is easy to strengthen the mechanical support for the winding, so that it can bear large electromagnetic force, especially suitable for transformers with large current. Shell structure is also used for large-capacity power transformers.

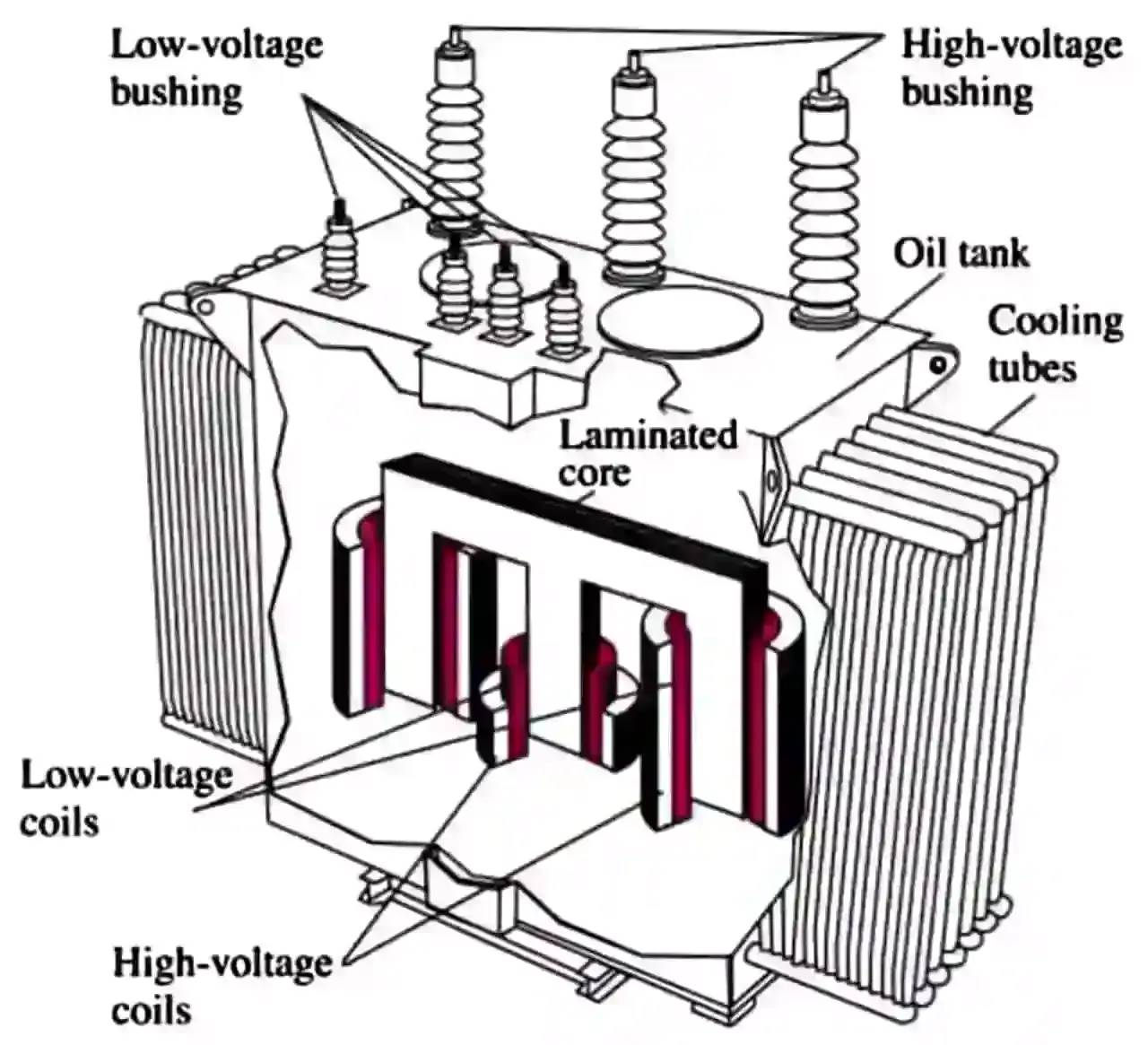

In a large-capacity transformer, in order to make the heat generated by iron core loss be fully taken away by insulating oil during circulation, so as to achieve good cooling effect, cooling oil passages are usually arranged in the iron core. The direction of the cooling oil channel can be made parallel or perpendicular to the plane of the silicon steel sheet.

Winding

Arrangement of windings on the iron core

According to the arrangement of high voltage winding and low voltage winding on the iron core, there are two basic forms of transformer windings: concentric and overlapping. Concentric winding, high-voltage winding and low-voltage winding are all made into cylinders, but the diameters of the cylinders are different, and then they are coaxially sleeved on the iron core column. Overlapping winding, also known as cake winding, has high voltage winding and low voltage winding divided into several cakes, which are staggered along the height of the core column. Overlapping windings are mostly used in shell transformers.

Core transformers generally adopt concentric windings. Usually, the low-voltage winding is installed close to the iron core, and the high-voltage winding is sleeved outside. There are certain insulation gaps and heat dissipation oil passages between the low-voltage winding and the high-voltage winding and between the low-voltage winding and the iron core, which are separated by insulating paper tubes.

Concentric windings can be divided into cylindrical, spiral, continuous and twisted types according to the winding characteristics.